Solutions for industrial applications

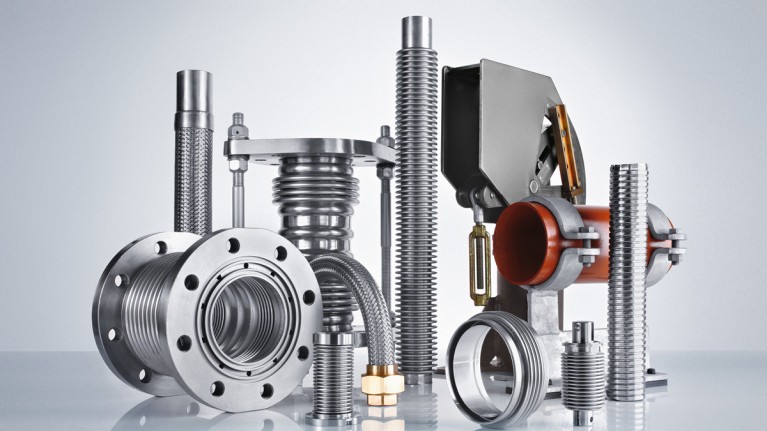

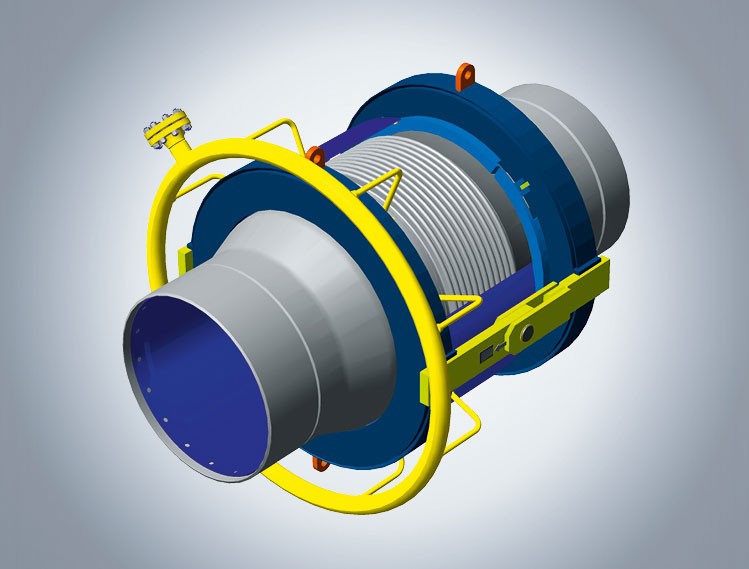

The Witzenmann Group is one of the world's leading manufacturers of flexible metallic elements such as flexible metal hoses, expansion joints, metal bellows and pipe supports. We are at home in all important industrial markets - in plant engineering and construction, in pipeline construction, device construction, mechanical engineering, in power plants and many other speciality markets.

Complete industrial product range

Engineering partner

Our engineering supports the customer in every phase. Starting with the first customer contact, finding the solution right up to installing the flexible component. This commitment has made us the leader in technology and service in our industry worldwide.

Design and Calculation

Using FEM programs such as Patran, Nastran and Marc, we create FE models as early as the design phase. For static and dynamic analyses. From hanger and pipe clamp to expansion joint or flexible metal hose. Thus, the components can be included in calculations with all requisite properties and without additional effort.

Engineering

Our entire engineering knowledge has been packed into our design program. This includes durability verification in accordance with the Pressure Equipment Directive, ASME and EJMA as well as our product configurator FLEXPERTE.

Product Tests

Witzenmann has modern testing technologies such as

- x-ray and ultrasonic tests (CTR)

- electron beam microanalysis (EDX)

- helium leak test

- test rigs for load cycle tests under operating conditions

Welding

We have all the necessary procedures, appropriately qualified welders and the approvals required:

- WIG, Microplasma, MIG/MAG, UP, E-Hand

- Laser welding (solid laser, CO2 laser, and diode laser)

- Resistance welding (spot-welding, seam, and projection welding)

- Brazing (induction / furnace brazing)

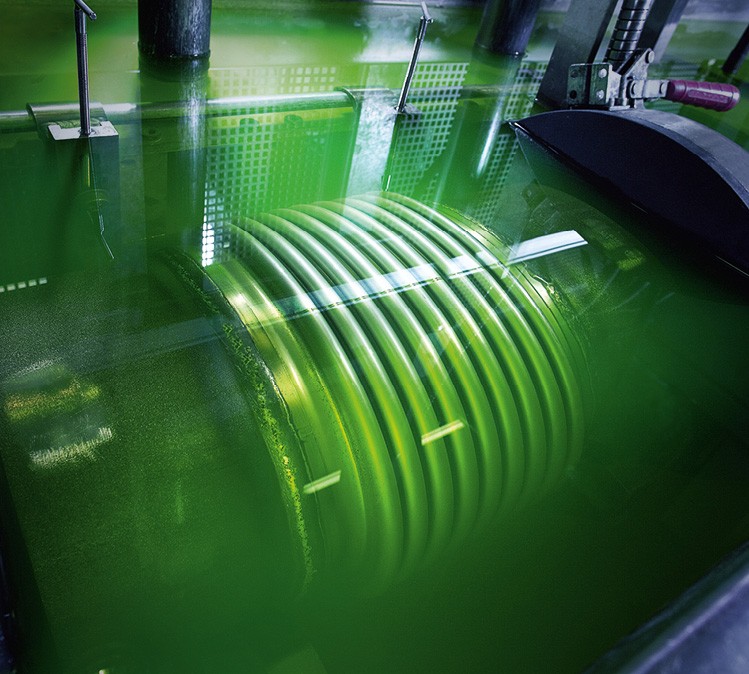

Materials

In our materials laboratory, we study the suitability of materials for specific application cases. For this purpose, a broad range of experimental and testing ordinances are available to us, such as:

- Weld seam testing (non-destructive, destructive)

- Heat treatment of materials (hot and cold test rigs)

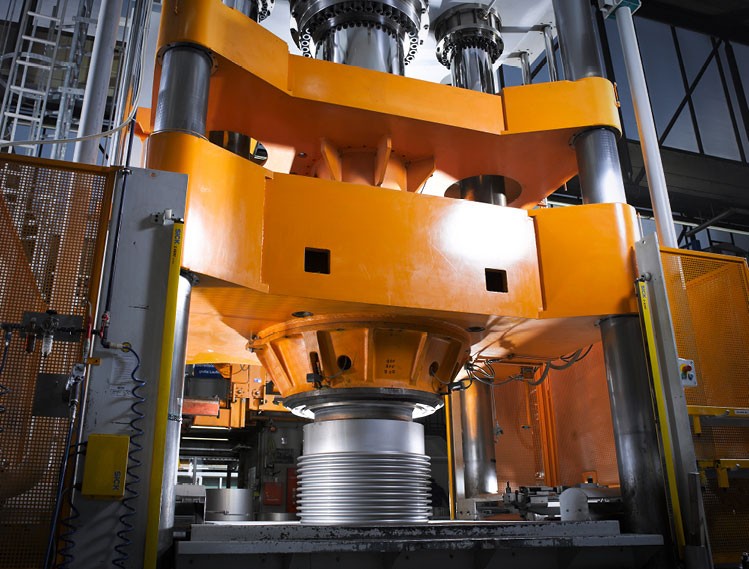

Production

The Witzenmann Group has production sites worldwide. The most modern production methods and our production network form the basis for rapid and economical manufacturing.

Our core competencies include:

- Cutting, reshaping and welding thin-walled materials

- Working with nickel-based alloys

Service

For complex components, where very high safety requirements apply or difficult installation conditions exist, we are also there on site. With engineering expertise, from the installation to starting up the system.

Facts & Figures

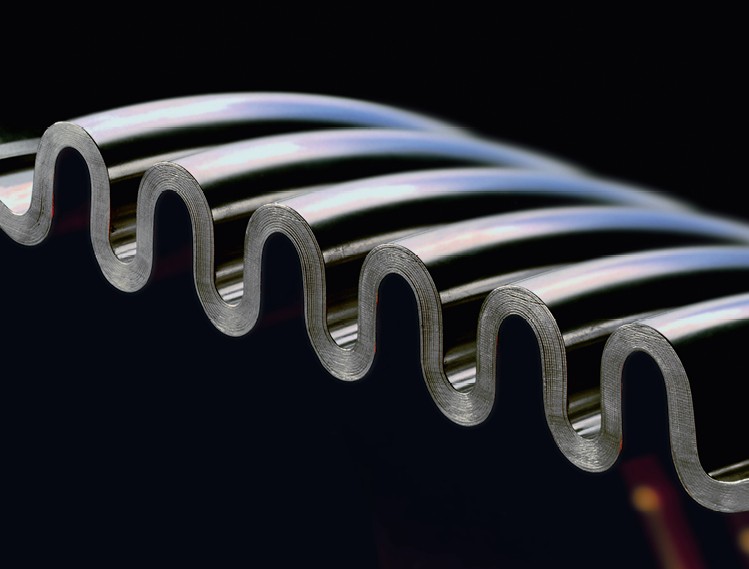

Multi-ply: extreme flexibility, short overall length

Approvals

There for you, worldwide

You may also be interested in

Next steps

Downloads

Configure products

Use our FLEXPERTE tool to configure products, quickly and easily, to meet your individual requirements.

Details:

- Design of standard products

- Creation of data sheets

- Preparation of Enquiries

Download: FLEXPERTE customer version

FLEXPERTE: The design program for the Witzenmann Group's entire product range with function-specific subdivisions

- Flexible metal hoses

- Expansion joints

- Metal bellows

- Bearings, hangers, supports

Additional questions

Nothing beats direct contact. We are happy to take the time for a personal discussion with you to answer your questions on an individual basis.

Please send us an inquiry using the contact form, and we will immediately get back to you.